The CTTÉI is actively involved in applied research to reduce at source, reuse, recycle and recover critical and strategic minerals (CSMs).

He is a member of theEnergy Squad of the CCTT Network - Synchronex, which helps Quebec companies improve their energy performance.

Critical minerals

SCMs are essential to support Quebec's energy and technology transition. These minerals include copper, graphite, cobalt, lithium, nickel, silicon, silver, neodymium, lead, platinum, tantalum, tellurium, zinc, magnesium and rare earth elements. They areindispensable components in the manufacture of technologies and infrastructures deemed necessary to decarbonize our activities. We're talking here about wind turbines, solar panels, electric car batteries, CO2 capture and storage equipment, but also electronic devices, surgical instruments and aircraft engines.

Demand for SCMs is growing, and their supply must be secure from both an economic and an environmental point of view. We need to ensure that the deposits are available and that extraction is acceptable for the health of humans and ecosystems.

In the same way as improved energy efficiency in all areas of the economy, optimal supply and wise use of SCMs will contribute to the decarbonization of our economy. That's why the provincial and federal governments are proposing programs to improve the entire value chain in the metallurgical and mining industries.

The CTTÉI at the service of the MCS circular economy

Characterization of MCS

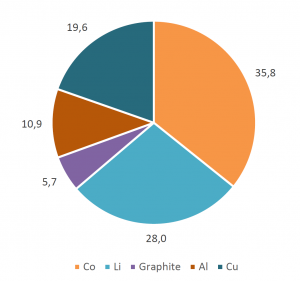

In 2022, the CTTÉI carried out a study to characterize the SCM value chain in Quebec, and analyzed the categories of products containing SCMs in the province. The study highlighted SCMs with high recovery and valorization potential, using criteria such as types of use, criticality, recyclability and the possibility of mineral substitution. For example, the analyses showed that lithium-ion cells and batteries from industrial systems or off-highway vehicles (OHVs) have good potential for second life, recovery and valorization.

The study sheds light on the importance of structuring recovery channels, encouraging the development and implementation of innovative recycling processes in Quebec and, ultimately, promoting the retention of SCMs by increasing the resilience of the Quebec supply chain to foreign economies.

Operations optimization and tailings management

In 2024, the CTTÉI was commissioned to find outlets for residual gypsum from mining operations. The aim is to minimize the impact of mining activities in Quebec by making maximum use of extracted materials. This is achieved by working upstream of mining projects on the choice of chemical inputs and the optimization of water consumption through the use of innovative processes. We are also in a position to research recovery and reuse outlets even before tailings are actually produced.

Management of SCM recycling residues

In 2023, the CTTÉI was commissioned to investigate ways of recovering shredded plastic fractions (light and heavy) from the recycling of end-of-life lithium-ion batteries. The mixed fractions studied consisted of mixtures of high-value SCMs, aluminum and plastics. The CTTÉI suggested separation methods and showed that it was possible to separate, and thus recover, aluminum and plastics. This makes it possible to recover both materials.

Aluminum has a number of outlets, including construction materials, refractory materials, the abrasives market, metallurgy, catalysis and recycling. For plastics, the main recovery routes are molding, mechanical recycling, chemical recycling (pyrolysis) and energy recovery.

Recycling: mechanical conditioning of alkaline batteries

In 2021, the CTTÉI developed a battery conditioning process that separates the components (electrode powder or black mass on the one hand, and enveloping materials such as plastic and steel on the other) and recycles them separately. The CTTÉI proceeded to crush, sieve, separate and recover these two large families of compounds safely and efficiently. As a result of this work, carried out in collaboration with the Centre national en électrochimie et en technologies environnementales (CNETE), the customer received instructions on how to effectively separate and package the batteries and their components on an industrial scale, so that they could implement it in their plant.

Recycling hard disk magnets to recover neodymium

In 2023, thanks to research funding from the Quebec government(PART program), the CTTÉI worked on the recovery of neodymium and rare earth elements from end-of-life HDD permanent magnets. Using solvometallurgy, we have developed a recipe for extracting these SCMs and reintegrating them into the production chain as non-virgin raw materials.

The results are promising, since various electronic products, such as computers, cell phones, headphones and electric vehicle batteries, contain magnets, as do HDD hard disks. Once they reach the end of their useful life, they constitute a deposit of neodymium and rare earth elements. These minerals are indispensable to technological development. The value of neodymium oxide is around CAD 67,000 per tonne.

Research has also led to increased knowledge of solvometallurgy. This clean process uses biodegradable organic compounds as solvents. Non-toxic, it is an alternative to hydrometallurgy. It is water-efficient, can generate less waste and requires fewer treatments. What's more, some of the solvents used to dissolve metals can be reintegrated into the process. This means less chemical waste and significant cost savings.

The CTTÉI will continue this work with a comparative analysis of hydrometallurgy and solvometallurgy processes under optimized conditions. We will produce a life-cycle analysis to better estimate the environmental and economic benefits of solvometallurgy.

SCM recovery from steelmaking dust

In 2024, the CTTÉI was awarded a research grant from the Quebec government(PART program) to study the recovery of zinc and silver by solvometallurgical processes from steelmaking dust, a by-product of steel production by the Quebec metallurgical industry.

The value of silver ranges from C$950 to C$1,350 per kilo. Zinc has a value of CA$4,400 per tonne. It is estimated that, for every tonne of steelmaking dust usually stockpiled or landfilled by the metallurgical industry, around 8% of the material could be recovered and thus diverted from landfill. The benefits are as obvious in terms of processing costs and resale potential, as they are in environmental terms.

SCM recovery from electronic scrap

The CTTÉI is working closely with the academic world on the recovery of SCMs such as copper and gold from electronic scrap such as computer circuit boards, using solvometallurgy.

In 2024, the CTTÉI will extend its research by collaborating with industrial players already involved in the recycling of electronic materials. Research will focus on the possible transition from conventional hydrometallurgy to solvometallurgy.

Industrial slag decontamination

In 2024 and 2025, the CTTÉI will use solvometallurgy to study the extraction of lead and other metals from lead slag, an industrial residue from metallurgical processing. The objectives of the study are: to downgrade the residual materials targeted in this project from the category of hazardous materials; and to explore a new route for the recovery of metals present in significant residual concentrations. Although lead is a heavy metal that does not appear on the list of SCMs, this project demonstrates the value of studying solvometallurgy in SCM-related processes, with a view to increasing the circularity of the entire metallurgical production chain.

The clean solvometallurgy process is now demonstrating its potential not only for the recovery of SCMs, but also for soil decontamination and the reclamation of mining and industrial residues.